Containerized Energy Storage System (CESS) is an integrated energy storage system developed to meet the needs of the mobile energy storage market. It integrates battery cabinets, lithium battery management systems (BMS), container dynamic environmental monitoring systems, and can integrate energy storage inverters and energy management systems according to customer needs. Containerized energy storage systems have the characteristics of simplified infrastructure construction costs, short construction periods, high modularity, and ease of transportation and installation. They can be applied to power plants such as thermal, wind, and solar power, suitable with specific situation such as islands, communities, schools, research institutions, factories, and large load centers Etc.

Container classification According to material classification Aluminum alloy container: Advantages are lightweight, beautiful appearance, corrosion resistance, good elasticity, easy processing, low processing and repair costs, long service life; Disadvantages are high cost, poor welding performance; Steel container: Advantages are high strength, sturdy structure, high welding performance, good water tightness, low price; Disadvantages are heavy weight, poor corrosion resistance; Fiberglass reinforced plastic container: Advantages are high strength, good rigidity, large volume, good heat insulation, corrosion resistance, chemical resistance, easy to clean, easy to repair; Disadvantages are heavy weight, prone to aging, reduced strength at bolt joints.

The design of the energy storage container mainly consists of two parts:

- Battery Compartment: The battery compartment mainly includes batteries, battery racks, BMS control cabinets, heptafluoropropane fire suppression cabinets, cooling air conditioners, smoke detection lighting, monitoring cameras, etc. The battery needs to be equipped with a corresponding BMS management system. The type of battery can be iron-lithium battery, lithium battery, lead-carbon battery, or lead-acid battery. The cooling air conditioner adjusts in real-time according to the temperature inside the compartment. The monitoring camera allows remote monitoring of the equipment’s operation status inside the compartment, forming a remote client to monitor and manage the operation status and battery status of the equipment inside the compartment through the client or app.

- Equipment Compartment: The equipment compartment mainly includes PCS and EMS control cabinets. PCS can control the charging and discharging processes, perform AC-DC conversion, and directly supply AC loads in the absence of the grid. EMS plays a significant role in energy storage system applications. In the distribution network, EMS mainly communicates with smart meters to collect real-time power status of the grid and monitor changes in load power in real-time. It controls automatic power generation and assesses the power system’s status. In a 1MWh system, the ratio of PCS to batteries can be 1:1 or 1:4 (Energy storage PCS 250kWh, battery 1MWh). 1MW containerized inverter heat dissipation design adopts the design of front air intake and rear exhaust, which is suitable for placing all PCS in the same container of the energy storage power station. The wiring, maintenance channels, and heat dissipation design of the container’s internal distribution system are optimized and integrated, which is convenient for long-distance transportation and reduces the cost of post-maintenance.

Components of Containerized Energy Storage System

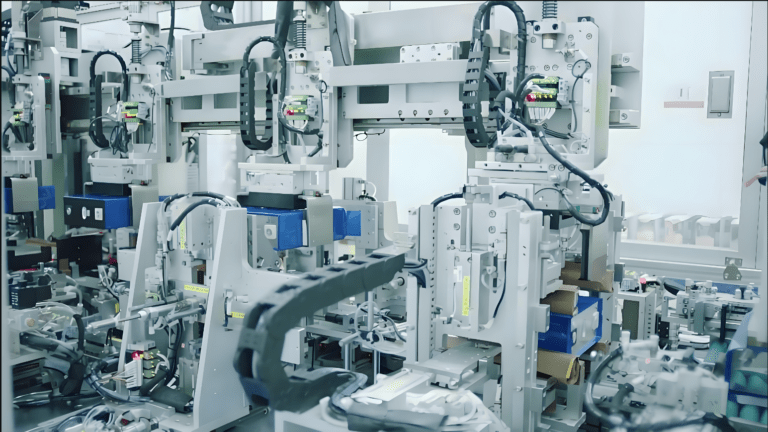

A 1MW/1MWh containerized energy storage system as an example, the system generally consists of energy storage battery system, monitoring system, battery management unit, dedicated fire-fighting system, dedicated air conditioning, energy storage inverter, and isolation transformer, all integrated into a 40-foot container. Battery System: Mainly composed of battery cells in series and parallel. First, a dozen groups of battery cells form a battery box through series and parallel connection, and then the battery boxes are connected in series to form a battery string to increase the system voltage. Finally, the battery strings are connected in parallel to increase the system capacity, and integrated installation in the battery cabinet.

Monitoring System: Mainly realizing external communication, network data monitoring, data acquisition, analysis, and processing functions, ensuring accurate data monitoring, high voltage-current sampling accuracy, data synchronization rate, and fast execution speed of remote control commands. The battery management unit has high-precision single-cell voltage detection and current detection functions to ensure the voltage balance of the cell modules, avoid circulating currents between battery modules, and affect the efficiency of the system operation.

Fire-Fighting System: To ensure the safety of the system, the container is equipped with a dedicated fire-fighting and air conditioning system. The system senses fire alarms automatically through smoke sensors, temperature sensors, humidity sensors, emergency lights, etc., and extinguishes fires automatically; the dedicated air conditioning system controls the air conditioning cooling and heating systems through heat management strategies based on external environmental temperatures, ensuring that the temperature inside the container is within a suitable range and extending the battery’s service life.

Energy Storage Inverter: It is the energy conversion unit that converts DC power from the battery into three-phase AC power. It can operate in grid-connected and off-grid modes. In grid-connected mode, the inverter exchanges energy with the grid according to the power commands issued by the upper-level dispatch; in off-grid mode, the energy storage inverter can provide voltage and frequency support for factory loads and provide black start power for some renewable energy sources. The energy storage inverter output is connected to the isolation transformer, completely isolating the primary and secondary sides electrically, ensuring the safety of the container system to the greatest extent.

Advantages of Container Energy Storage Systems

- Containerized energy storage units have good functions such as corrosion resistance, fire resistance, waterproofing, dustproofing (sandstorm prevention), earthquake resistance, UV resistance, and theft prevention, ensuring no corrosion within 25 years.

- The shell structure, heat insulation materials, internal and external decorative materials of the container all use flame-retardant materials.

- The air intake and exhaust ports of the container and the equipment’s air intake ports are equipped with replaceable standard ventilation filters, and they can effectively prevent dust from entering the container during large wind and sandstorms.

- The earthquake-resistant function ensures that the mechanical strength of the container and its internal equipment meets the requirements under transportation and seismic conditions, without deformation, abnormal function, or failure to operate after vibration.

- The UV-resistant function ensures that the properties of the materials inside and outside the container will not deteriorate or absorb the heat of UV radiation.

- The anti-theft function ensures that the container cannot be opened by thieves in outdoor conditions. It produces threatening alarm signals when thieves attempt to open the container and sends alarm signals to the background through remote communication methods. This alarm function can be shielded by the user.

- The standard unit of the container has its own independent power supply system, temperature control system, heat insulation system, flame retardant system, fire alarm system, mechanical interlock system, escape system, emergency system, fire protection system, and other automatic control and protection systems.

Lithium Battery Containerized Energy Storage System

Lithium battery energy storage systems are divided into cabinet-type energy storage systems and containerized energy storage systems according to the installation form. As energy storage systems shift towards longer durations, customers purchasing lithium battery energy storage systems will strengthen their demand for energy and power. Based on advanced lithium battery technology, lithium battery containerized energy storage systems are equipped with standardized inverter equipment and monitoring management systems, which can better meet the growing energy storage needs.